-

The proper choice of the raw material, the high skill-set of the staff and the know-how of the processes to follow are key in the boilermaking process.

-

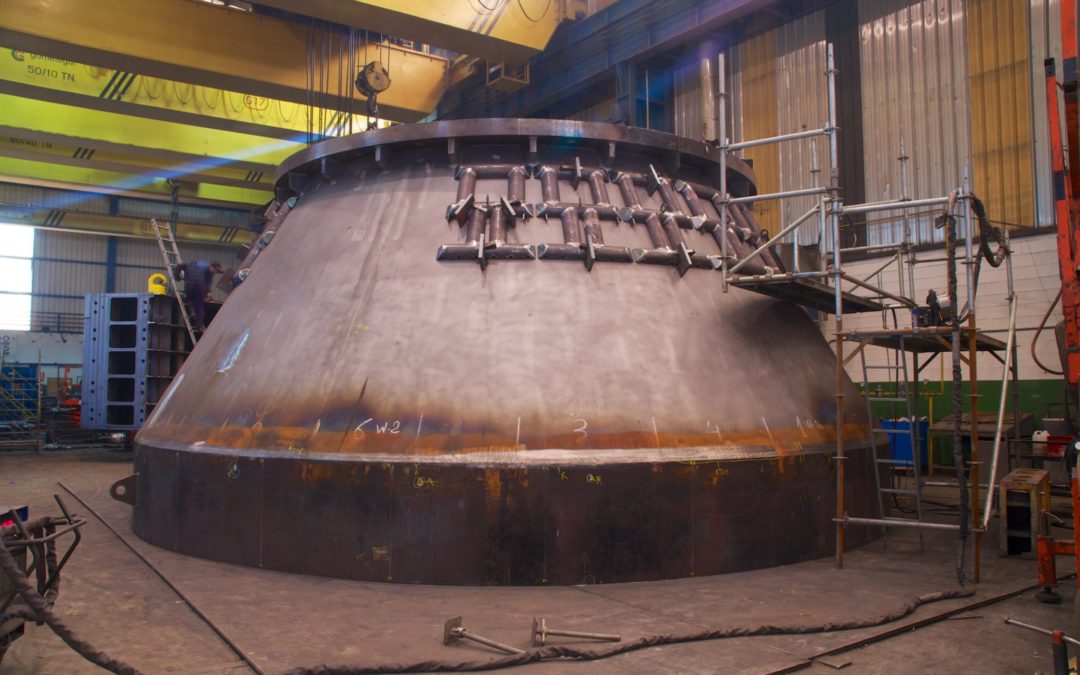

In Gometegui we integrate all the manufacturing processes for the manufacturing of large components for several sectors, such as wind energy, nuclear energy, steel industry, tunnel boring machines, hydraulic energy…

At Gometegui we assume each new project to manufacture components for heavy industry as a challenge, but with the certainty that it will be a complete success thanks to the experience of our workers and the rigor of our processes, among which are our solutions of boilermaking. The best guarantee is the satisfaction and trust of our clients in sectors as demanding as wind energy, nuclear energy, tunnel boring machines, hydraulic energy or the steel industry, among others.

One of the greatest competitive virtues of Gometegui is that we provide the complete solution to your project, from the purchasing of materials to logistics. In our extensive workshops of 10,000 square meters of covered area in Llodio (Álava), we tackle all the manufacturing phases which usually start with the heavy boilermaking. In the majority of projects this is the first process to produce any machined-welded component for heavy industry.

How do we manage the boilermaking process?

On the same page with our work methodology aimed at respecting deadlines, accompanying the client and guaranteeing the highest quality standards in heavy industry, the entire boilermaking process is planned to the millimeter to obtain the best results.

- After setting the planning to follow and sharing it with the team, the first step is to determine what materials will be needed. We made this step based on our experience, our resources and facilities and the customer’s requirements.

- The Purchasing Department emphasizes in selecting the best suppliers for the raw material.

- The Production Department plans and allocates all the necessary resources to guarantee compliance with the planning.

- Once the raw material has been received, our staff verifies and controls it. This is a critical process to guarantee that the final result remains optimal.

- The boilermaking service is completed with different tracing works, preparation of material, assembly of the parts, bending… All these processes are undertaken, taking into account the assembly and welding sequences planned. The aim is to achieve the correct geometry of the components before machining.

The know-how and the human team make the difference

In the case of boilermaking, the added value of Gometegui is clear from the very beginning with the supply of materials and their reception. Our team carries out a rigorous work with our suppliers to guarantee the quality of the raw material and prevent further problems in the project. In the event that any non-conformity is detected, we offer the appropriate solution to always guarantee the quality required by the client.

Our commitment to the most demanding technological requirements allows us to manufacture complex components. In the boilermaking process some difficulties may arise during the manufacturing process that are resolved by our experienced staff and always in continuous communication with the clients.

This collaboration and desire of service to the heavy industry extend are extended to those cases in which the client’s specifications cannot be executed in manufacturing. We advise our customers by providing the best manufacturing solution in those cases.

A wide selection of machinery

We count on a wide selection of machinery, which includes cutting machines, bending machines, laser tracker, and other specific tools to lift and manipulate large components.

Our boilermakers work under the requirements of the ISO9001, ISO18001 and ISO 45001 quality regulations. Currently, we are implementing ISO 3834 and EN-1090, without forgetting that all our processes are audited by companies such as Aenor, Bureau Veritas, Verus , Lloyd’s, as well as for our most demanding clients.

Recent Comments