-

This time we have manufactured a Spider rotor for the hydroelectric power station in Ottensheim, Austria

-

The project demanded great requirements, but we managed to achieve client satisfaction by fulfilling all the requests

At Gometegui, we manufacture components for the heavy industry. Among others, we work in the hydroelectric sector. Our most recent project in this field was for one of the most important companies worldwide, GE Hydro.

Are you looking for a solution for the hydroelectric industry? Contact us!

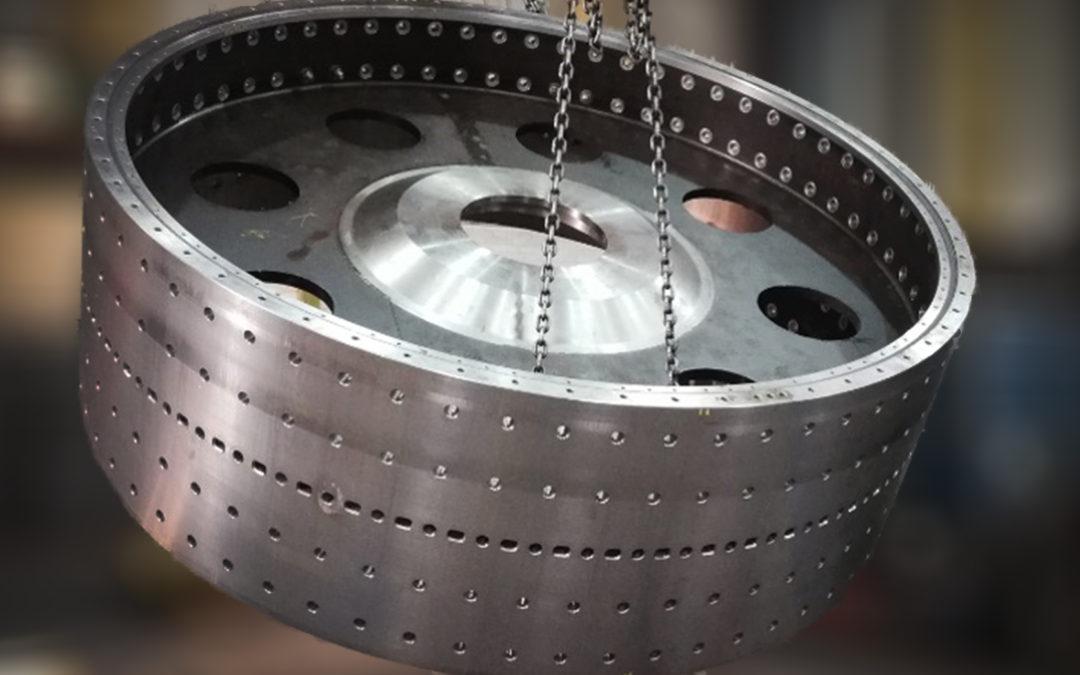

This time, we are responsible for the complete manufacture of the component to be installed in the hydroelectric power station in Ottensheim, Austria: a Spider rotor.

GE needed this solution and we made it easy and reduced manufacture times, difficulties and costs. All this help was provided from the beginning, when the project was still in the bidding phase, which led to a better approach to offer to their client and winning the order to be manufactured by us later on.

Given our experience and the projects successfully carried out with us, GE decided to entrust us with the manufacture of the Spider rotor. Moreover, this was a task previously carried out by one of our competitors. However, Gometegui’s good work in recent years together with GE was crucial for being assigned with the project. Do you want to know why such a large heavy industry company comes to us for component manufacturing with such strict standards? We recently published a post about our virtues, click here to read it.

What is a Spider rotor?

This is one of the most important parts of a vertical hydroelectric generator, which transfers torque and rotation from the axis to the rotor rim and poles.

The reason for success

In addition to providing the required solution in advance, we adapt, as we do in all projects, to the client’s requirements in terms of quality, deadline and reporting with constant and fluid communication.

The development of all the processes carried out without the need to subcontract and have other workshops validated was also a plus in terms of meeting deadlines.

How did we do it?

We manufactured this 32-tonne Spider rotor with more than 5 meters in diameter and close tolerances in 15 weeks, meeting every requirement. The process was as follows:

- Purchase and pre-machining of materials

- Welding of joints

- Rolling process

- Boring

- Preparation for the painting process

- Painting process

- Packaging

Component transport was also at our expense. In fact, it was one of the buyer’s requirements since, due to the dimensions of the rotor, special permits are needed to pass through several European countries.

Client satisfaction reflects a job well done. GE has told us that more Spider rotors will be installed at the Ottensheim station, and that, after this work, there is a good chance that we will be awarded the project.

Recent Comments